24/04/2018 -Box Clasp

I've been looking forward to today. We're making a box clasp.

Part of the bracelet spec was to incorporate the catch into the design of each link.

For those who didn't manage that, this provides an opportunity to make a catch for their bracelet, and is a learning opportunity for the rest of us.

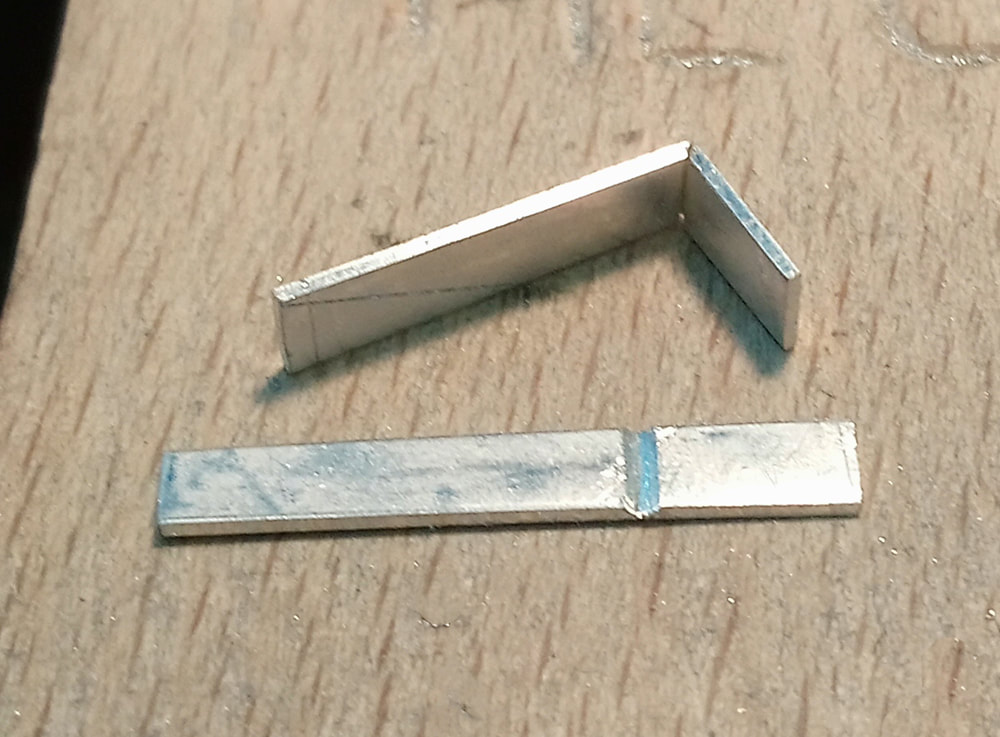

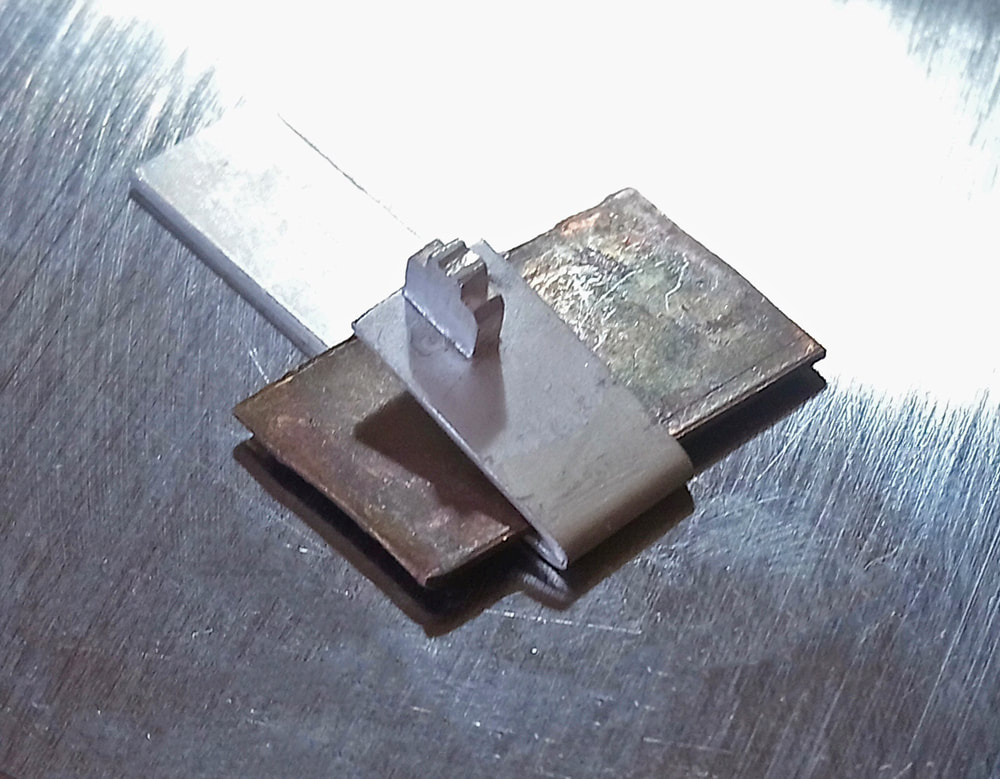

A 50x4mm strip of 0.7mm silver strip, was cut in half.

8mm from the end of each half, a 90degree score was made with a file.

They were then folded into two L shapes.

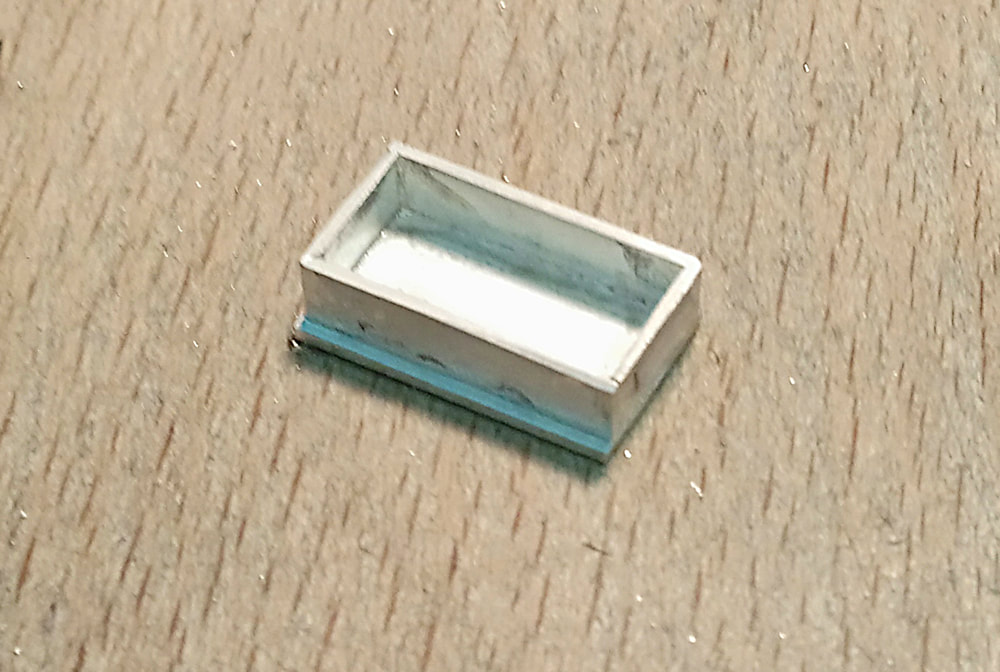

These were then placed together to form a box and soldered (including down the fold).

This box was then soldered onto a suitable sized piece of sheet and the excess cut away.

Part of the bracelet spec was to incorporate the catch into the design of each link.

For those who didn't manage that, this provides an opportunity to make a catch for their bracelet, and is a learning opportunity for the rest of us.

A 50x4mm strip of 0.7mm silver strip, was cut in half.

8mm from the end of each half, a 90degree score was made with a file.

They were then folded into two L shapes.

These were then placed together to form a box and soldered (including down the fold).

This box was then soldered onto a suitable sized piece of sheet and the excess cut away.

A 1.5mm strip was then cut away from one of the short sides. This will form the slot into which the tongue will enter the box.

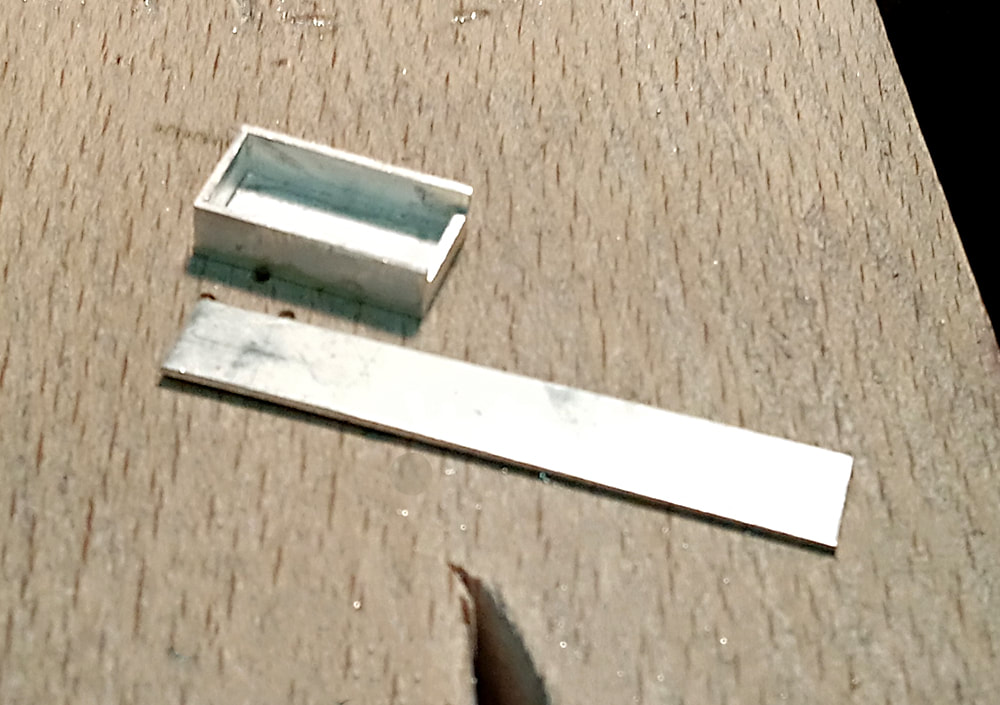

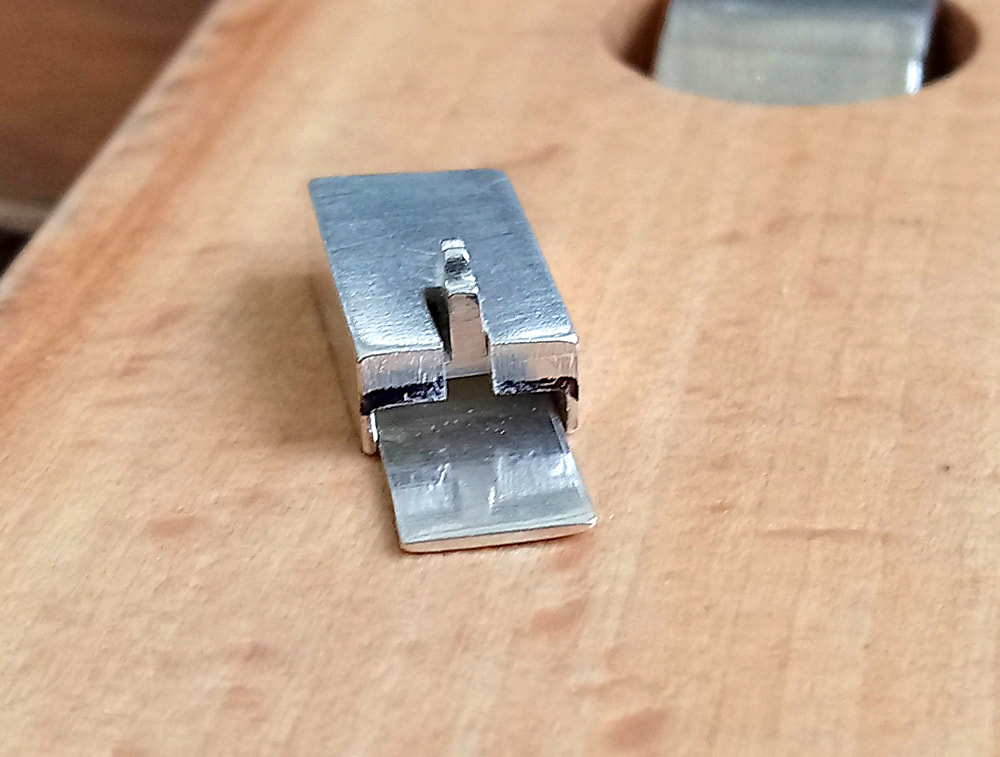

Next, a strip of sheet was cut that fitted snugly inside the width of the box, and was twice the length plus a few mm extra.

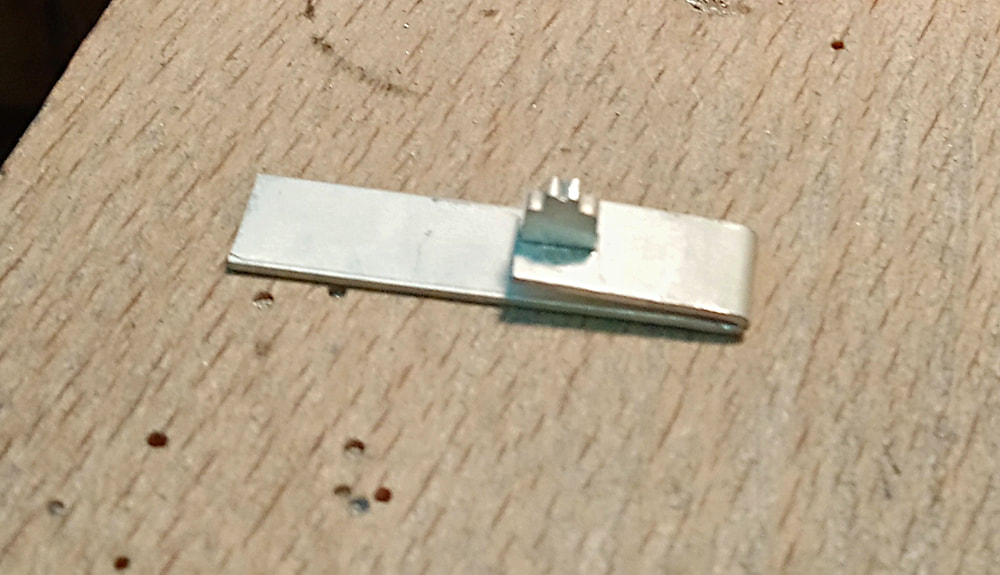

We next cut a 4mm high "button" with a groove for the fingernail to simultaneously push the tongue down and pull it out.

This was soldered into place in the centre of one end of the strip.

The internal length of the box was measured and the strip was scored (very lightly with a saw blade only) at this distance minus 1.5mm. N.B. The score was on the opposite side to the button.

Next, a strip of sheet was cut that fitted snugly inside the width of the box, and was twice the length plus a few mm extra.

We next cut a 4mm high "button" with a groove for the fingernail to simultaneously push the tongue down and pull it out.

This was soldered into place in the centre of one end of the strip.

The internal length of the box was measured and the strip was scored (very lightly with a saw blade only) at this distance minus 1.5mm. N.B. The score was on the opposite side to the button.

The strip was folded back on itself and a piece of sheet metal inserted.

The fold was then hammered to work harden it and provide the spring needed for the clasp to work.

The fold was then hammered to work harden it and provide the spring needed for the clasp to work.

A lengthways slot was then cut to allow the button to slide into the box far enough for the tongue too pass the wall and click into location.

A bottom piece of sheet was then soldered in place to complete the box.

A bottom piece of sheet was then soldered in place to complete the box.