22/02/2018 -Milliput

I had dismissed my wooden planks idea (inspired by Birnbeck Pier) a few weeks ago because I didn’t think I'd be able to successfully engrave the woodgrain pattern.

I knew exactly how I'd make the master pattern in silver clay, but I assume that's not allowed.

So I abandoned this idea in favour of the layered geometric design based on the pixellated wood patterns on Purton Hulks.

I had developed the design to the point of having a cutting plan, when I heard a rumour that Vanessa was going to give us a milliput demonstration.

If we're getting a demo, that must mean we're allowed to use it!

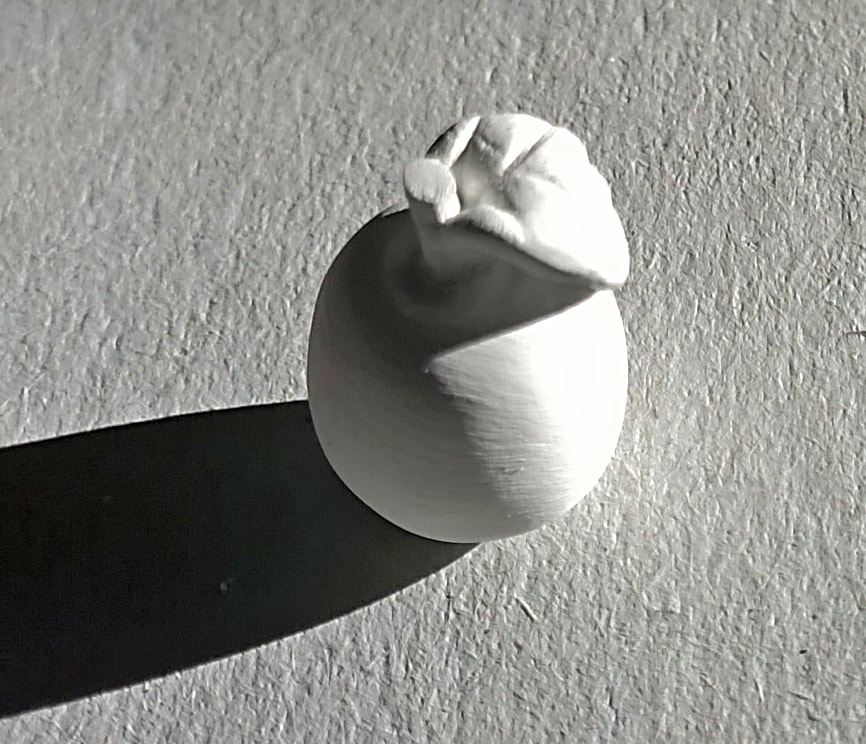

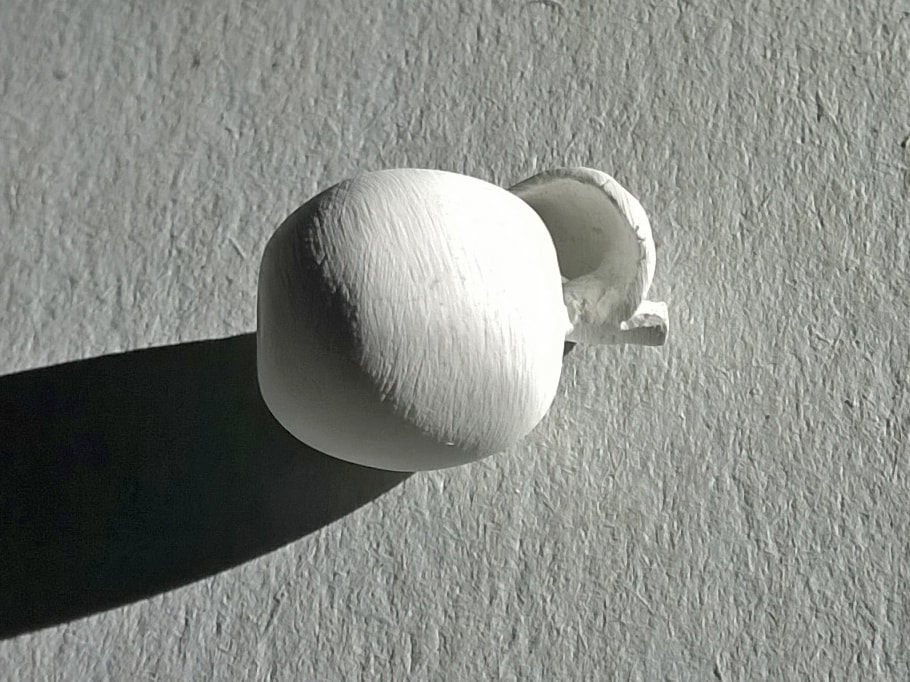

Just to try out the medium, we all made apples. No problem for me as I spent my entire childhood doing similar stuff with Fimo.

This stuff is much more messy though. Sticky to start with, requiring many minutes of mixing the two parts together by hand. Then quickly setting, leaving only a narrow window to work with. Basically, you need to know exactly what you're aiming for BEFORE you start.

Once it has started to set (this might be over night at room temperature, or a matter of minutes with heat) it has a very nice consistency for filing and sanding, but is very tough when fully cured.

One thing to bear in mind, is that it is not possible to create a traditional rubber mold from a Milliput master, RTV (Room Temperature Vulcanising rubber) must be used instead which is more expensive.

I knew exactly how I'd make the master pattern in silver clay, but I assume that's not allowed.

So I abandoned this idea in favour of the layered geometric design based on the pixellated wood patterns on Purton Hulks.

I had developed the design to the point of having a cutting plan, when I heard a rumour that Vanessa was going to give us a milliput demonstration.

If we're getting a demo, that must mean we're allowed to use it!

Just to try out the medium, we all made apples. No problem for me as I spent my entire childhood doing similar stuff with Fimo.

This stuff is much more messy though. Sticky to start with, requiring many minutes of mixing the two parts together by hand. Then quickly setting, leaving only a narrow window to work with. Basically, you need to know exactly what you're aiming for BEFORE you start.

Once it has started to set (this might be over night at room temperature, or a matter of minutes with heat) it has a very nice consistency for filing and sanding, but is very tough when fully cured.

One thing to bear in mind, is that it is not possible to create a traditional rubber mold from a Milliput master, RTV (Room Temperature Vulcanising rubber) must be used instead which is more expensive.