Fine Jewellery Techniques (JEW4035)

27/04/2018 - Final Build 3

This morning on the train, I was thinking about the final assembly of my orrery, and whether the central rivet would be firm enough to stop the central cog from rotating, but loose enough to allow the arm to rotate. I decided my design had a fatal flaw!

Could I make a countersink with grooves that the metal of the rivet would move into, just like a cross head screw? It would be risky, and I wouldn't find out until the last minute if it wasn't going to work.

I asked Katy for advice, and we brainstormed a couple of ideas. She suggested laser welding the cog onto the central tube, but I was reluctant as I’ve never used a laser welder, and think it would be cheating to use a technique we haven't covered.

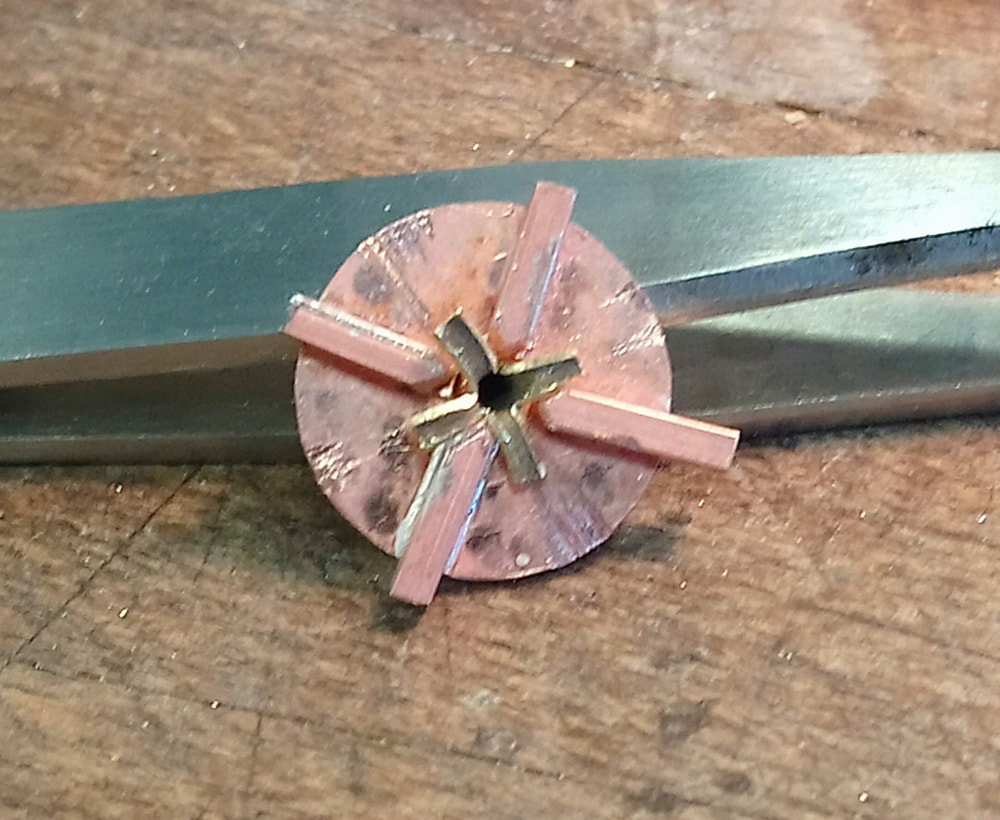

So I tried an experiment. I made two lengthwise cuts in a piece of tube, creating 4 separate “petals”. These could be bent downwards to create a cross.

I then cut out a circle of sheet, drilled a central hole, and soldered on some wire to form another cross.

The flared tube sits perfectly inside this cross which prevents it from rotating.

However I don't think my bezel is tall enough to accommodate any more material in the bottom, so I've just got to hope that I can burr out enough to make deep enough grooves.

Could I make a countersink with grooves that the metal of the rivet would move into, just like a cross head screw? It would be risky, and I wouldn't find out until the last minute if it wasn't going to work.

I asked Katy for advice, and we brainstormed a couple of ideas. She suggested laser welding the cog onto the central tube, but I was reluctant as I’ve never used a laser welder, and think it would be cheating to use a technique we haven't covered.

So I tried an experiment. I made two lengthwise cuts in a piece of tube, creating 4 separate “petals”. These could be bent downwards to create a cross.

I then cut out a circle of sheet, drilled a central hole, and soldered on some wire to form another cross.

The flared tube sits perfectly inside this cross which prevents it from rotating.

However I don't think my bezel is tall enough to accommodate any more material in the bottom, so I've just got to hope that I can burr out enough to make deep enough grooves.

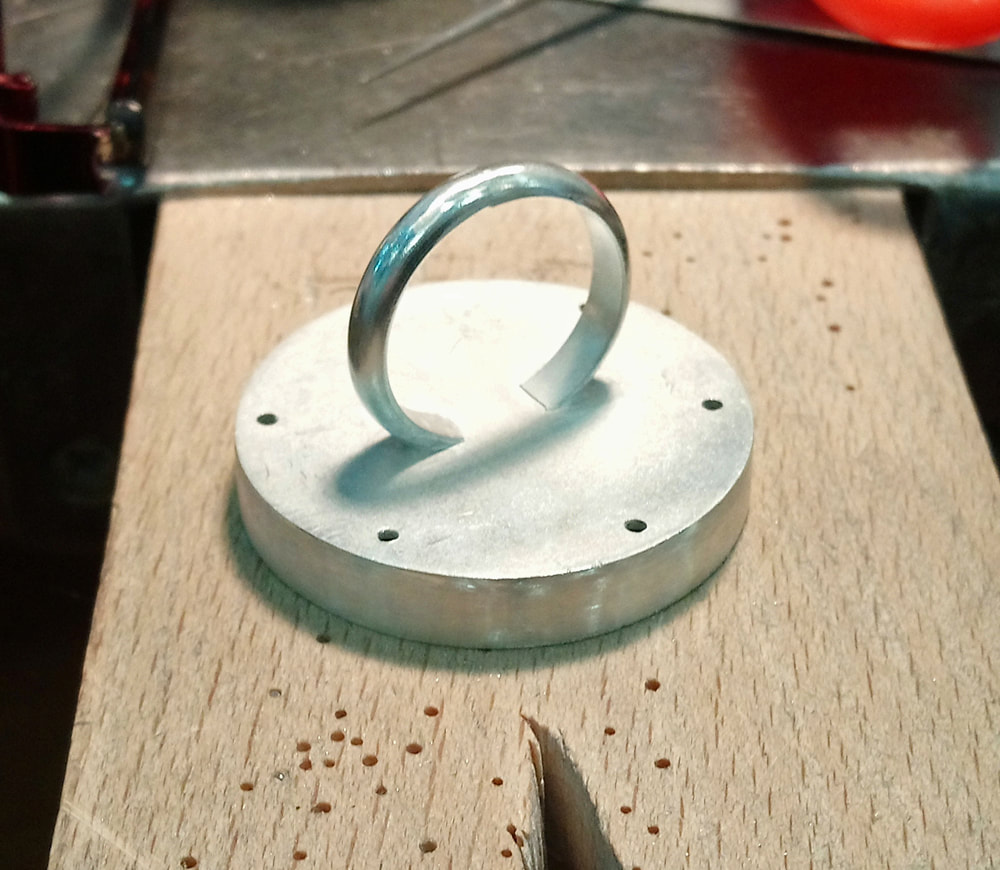

Once I’d come up with a plan, I could make some progress, and I made a ring and soldered it to the main cup. I also soldered a simple piece of round wire onto the arm to form a handle, and a small disk underneath to balance out the rivet that will be on the underside of the opposite end.