19/02/2018 -Group Crit

|

So we've spent weeks designing our bracelet links and today we're getting together in small groups for a "crit". Casting (no pun intended) an eye over each others work to make sure we've got a feasible concept.

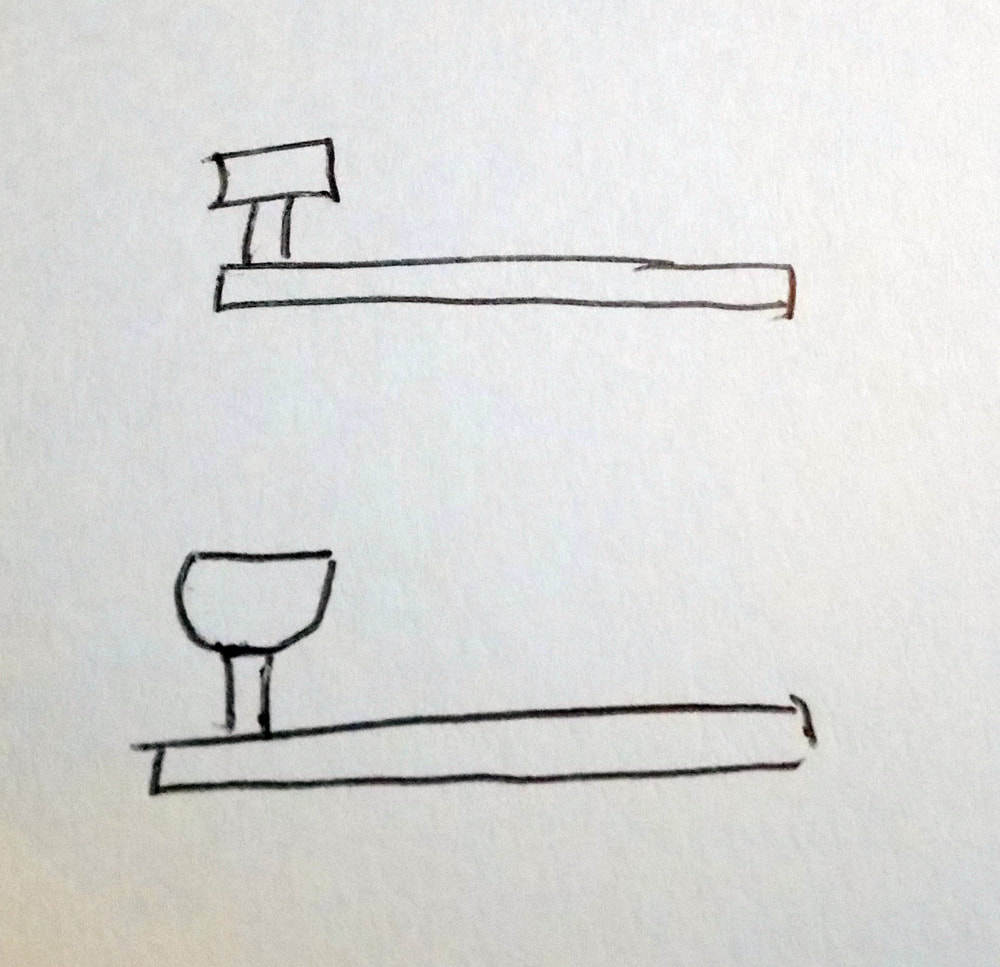

While this was happening, Steve from JHF went round to give some much needed advice to a few lucky people. I was not one of them and my subsequent master pattern build suffered for it. I did however get something useful out of it. Hamed pointed out that there is no room for vertical movement in my design, which was true. Whilst it will slot together fine, it will be very rigid like a bangle. My solution is to put curve on the bottom of the link as shown in the sketch (or even make it a round rod). |

20/02/2018 Casting Advice

Although we didn't all get to talk to Steve yesterday, some words of wisdom were relayed to us the next day.

- Min thickness after buffing 0.7mm

- Min hole size 1mm

- Min tube wall thickness 0.7mm

- Finish should be sharp and perfect

- 3-5% shrinkage

- Overall size must allow space around for cutting mold

- Best to solder on sprue yourself so you can place it where it will do the least damage

- Master pattern should be silver or gilding metal, as copper tends to stick to the rubber mold