14/12/2017 Press Forming

|

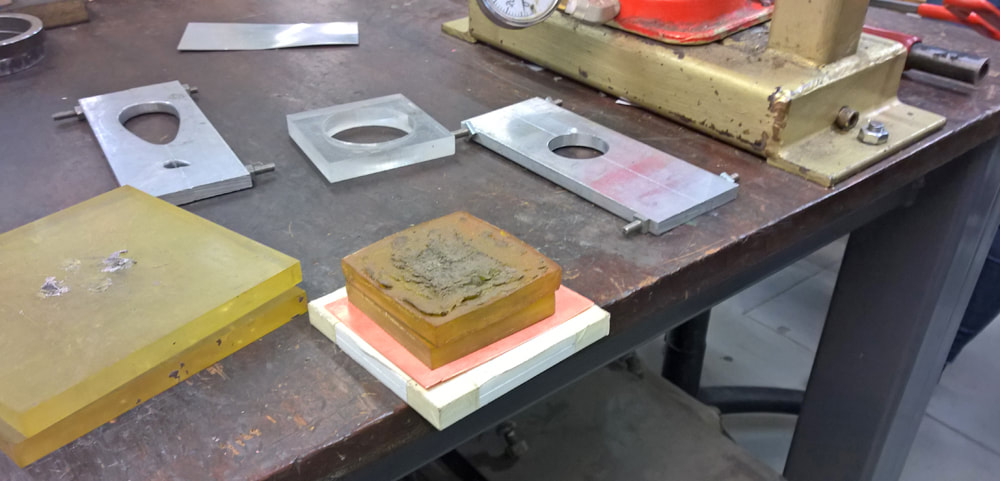

Press forming is done using a number of layers of different materials.

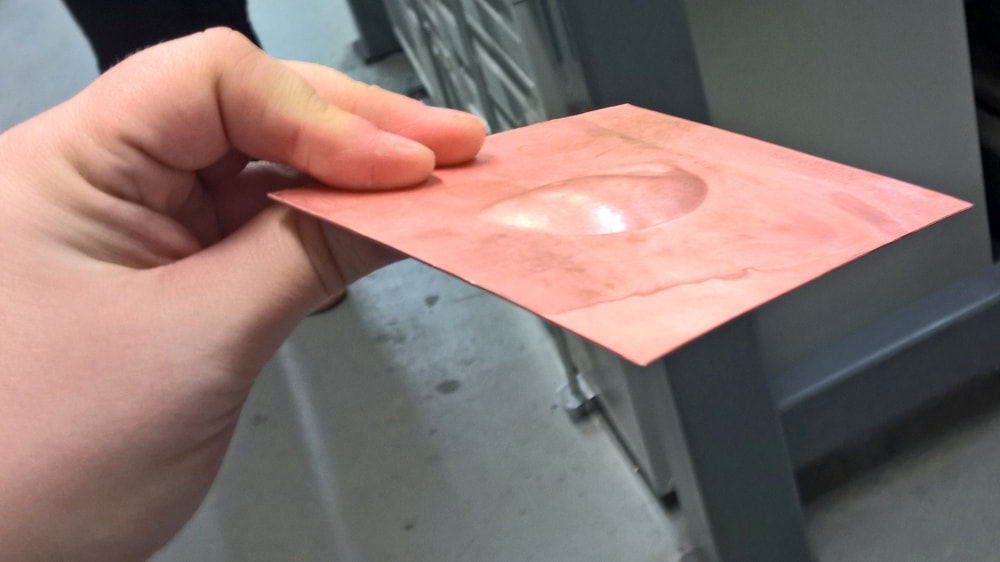

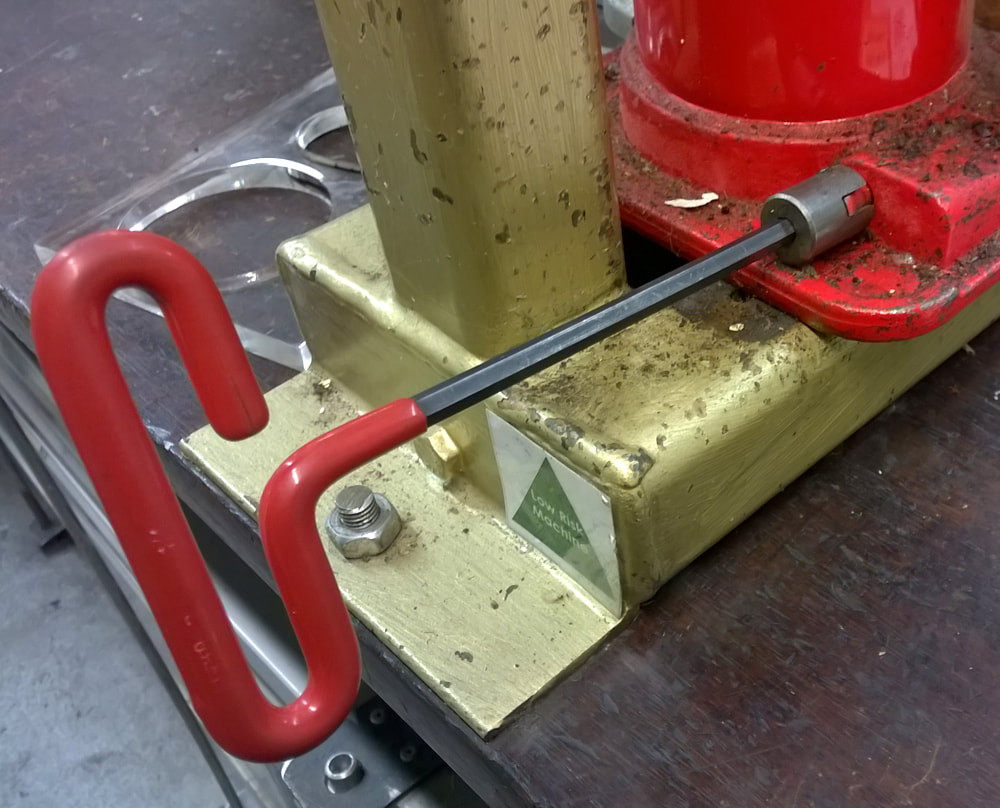

The metal sheet to be shaped is placed between a perspex die (a thick slab with the desired shape cut out of the centre) and thick flexible rubber. Other materials can be used instead of perspex but it can be easily laser cut which is why it’s preferable (if you have the facilities). When compressed, the metal sheet is pushed though the die by the rubber, forming a domed 3D shape. The metal may have to be reannealed several times to get the desired depth, and subjecting it to excessive pressure may cause the domed section to split away from the rest of the sheet. Press forming is only suitable for largeish, rounded shapes. Finer detail may be enhanced by placement of small pieces of rubber or blu-tack. |

|