|

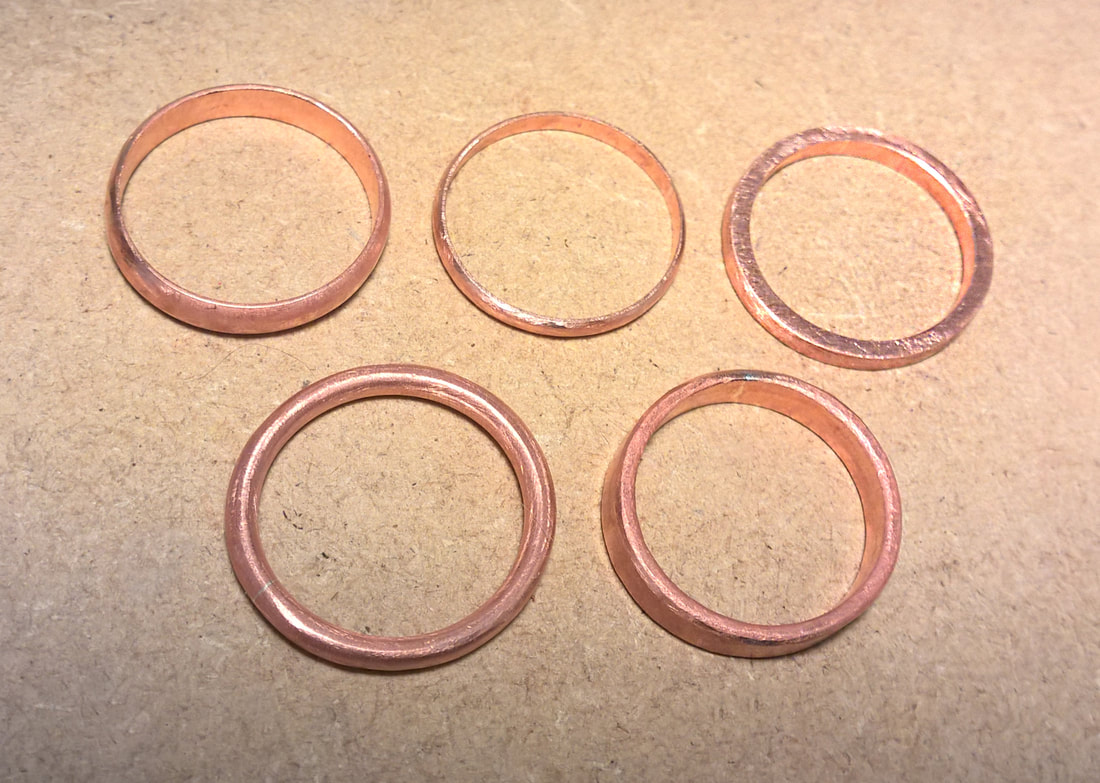

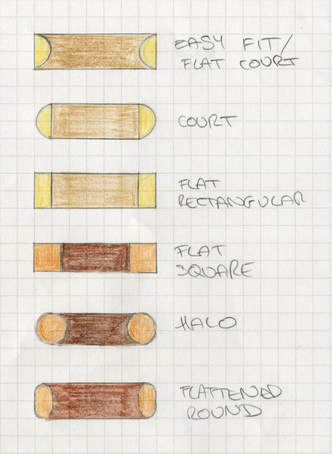

First couple of days of our first module and, as I expected, we're making basic rings. We started with a simple D-shaped wedding band. Made in brass that had been shaped with the rolling mill. As I HATE wasting silver, I've always cut my wire to length and simply soldered the ends together. However we used the other technique I've heard about, bending the wire round until it overlaps and then cutting through the two widths (as shown below). I can see merit in both methods and I think time will tell which one I opt for in the future. However you can be pretty sure the size will be accurate with the method we used here (we were aiming for an N), as the ring is pretty much fully formed and it can be measured and/or tried on. I have in the past, cut wire to length very precisely, and mysteriously ended up with a ring of totally the wrong size. Edit: As it turns out, all these rings came out at O½, so not quite as accurate as I thought.

Comments are closed.

|

ContentsIndex

All

Archives |