|

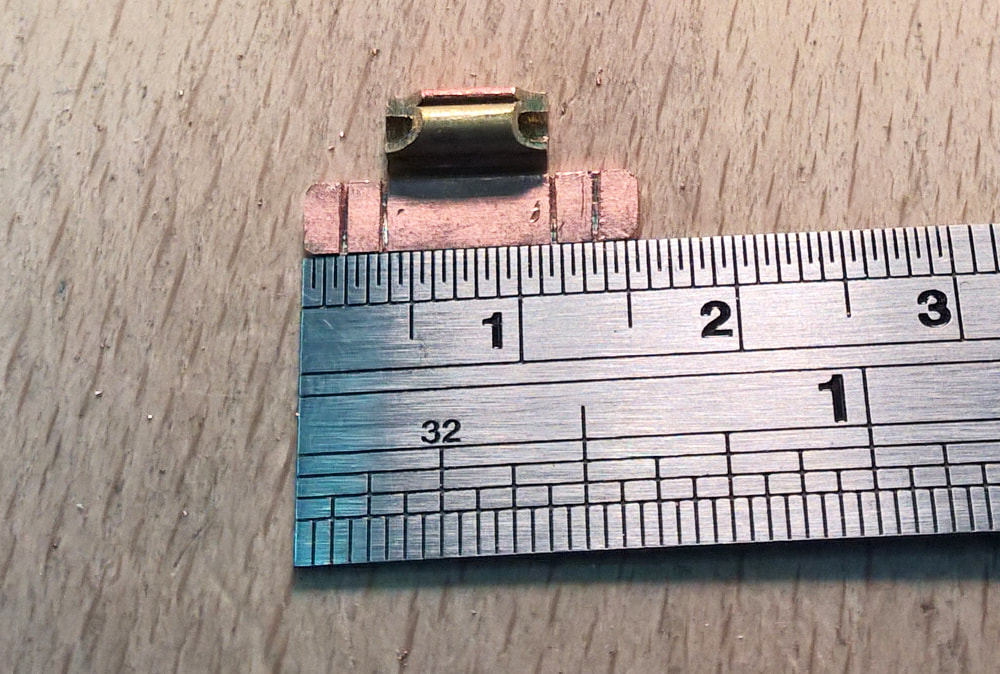

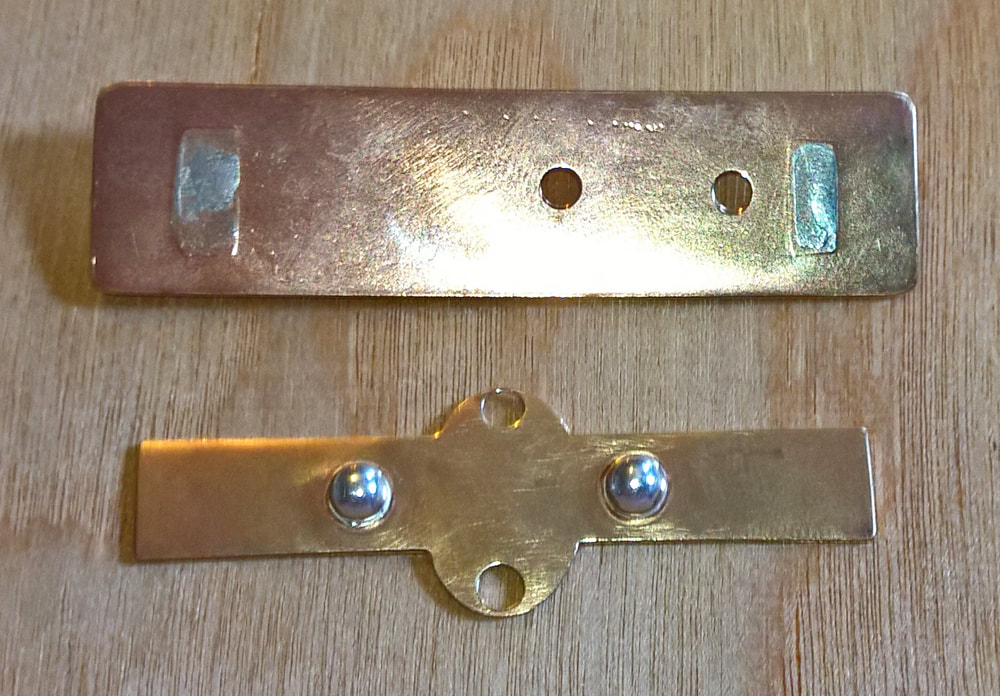

On Friday we made a bezel setting for a glass cabochon. Using tube left over from the hinged ring, we soldered short tube rivets onto the back of the bezel. Today we're going to make the plain bar brooch back that the cabochon setting will be riveted to.

Comments are closed.

|

ContentsIndex

All

Archives |