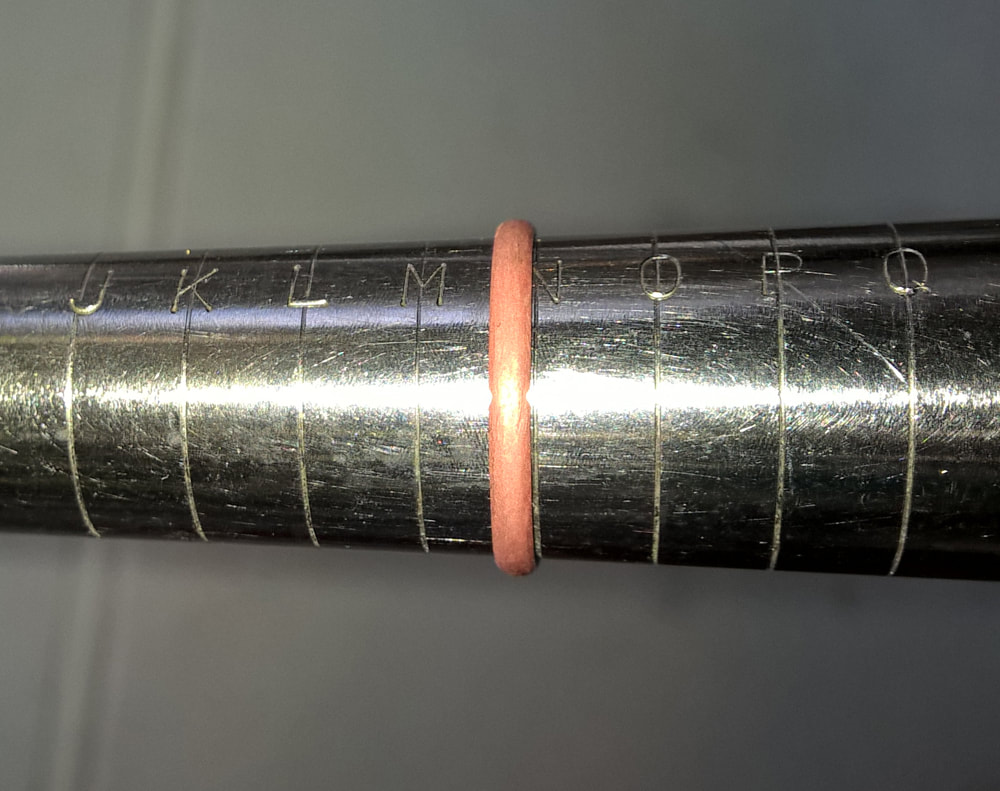

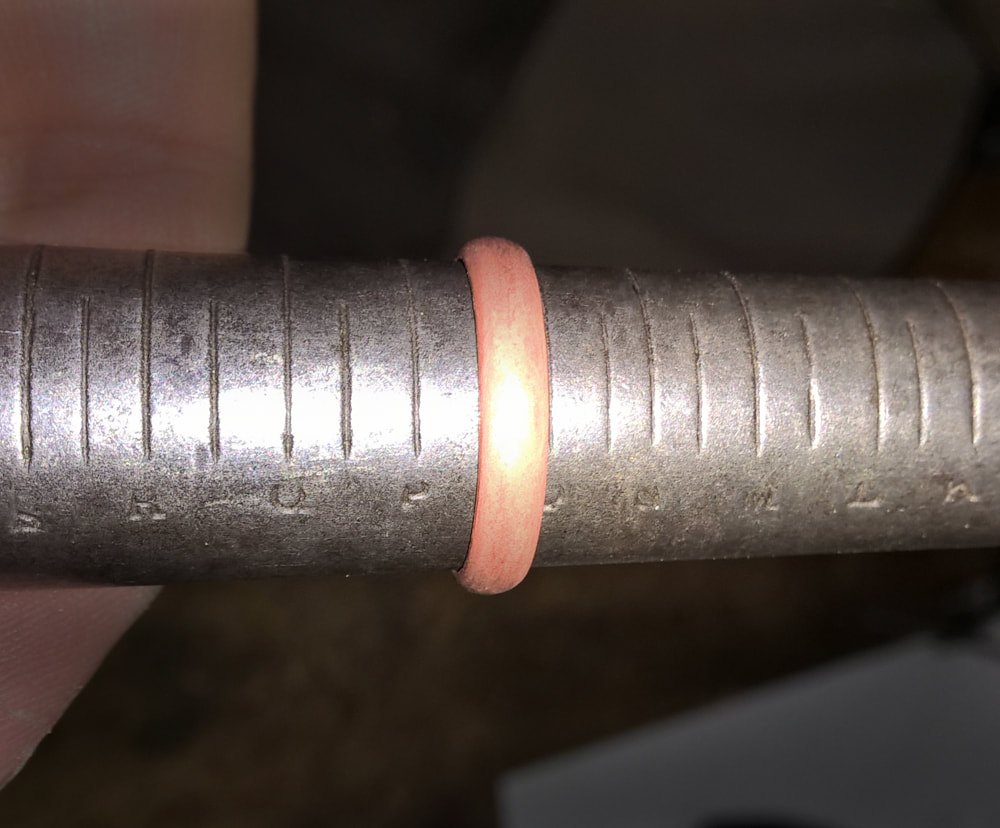

The length of new wire required to increase the ring by 3 sizes was only a few mm. This made holding it very difficult. A number of us resorted to using parallel pliers to grip one end while the other was filed. Even then it was hard to get the file at the right angle. Although we were told to use a triangular file to make the Vs, I think that a square file is much better. I find a right angle is easier to gauge by eye, and the shallower angle makes filing the new material into points much easier when there’s so little material to grip. I wonder if you did this kind of resizing often, whether it would be worth keeping a stock of ready made inserts in various metals and various lengths... Anyway, after a lot of careful filing on both the Vs and the points, I was satisfied with the fit and soldered the insert into place and cleaned up the newly resized ring. I then used the same technique on a D-shaped court ring but found it harder to get a nice thin solder join on this shape.

Comments are closed.

|

ContentsIndex

All

Archives |